|

|

|

|

|

Topic: Printable maintence schedule

|

Email this topic to a friend |

Subscribe to this Topic

| Report this Topic to Moderator

|

|

Page 1 of 1 of 6 replies

|

|

|

|

|

December 06, 2014 at

12:01:08 AM

|

|

|

Joined:

|

07/16/2008

|

|

Posts:

|

979

|

|

|

|

Is there anywhere online where we can find a printable weekly and seasonal maintence checklist /schedule? We could come up with our own but seeing the format of somebody elses would help us out greatly. Thanks in advance.

|

|

|

|

|

December 06, 2014 at

11:14:04 PM

|

|

|

Joined:

|

10/24/2012

|

|

Posts:

|

61

|

|

|

|

Well, I have not won a feature in anything other than "support classes" and (because of this list and no shop help) was usually the last one to the track...lol, but I put this together. (Length of this and time it takes to complete, are the reason I charge what I do for my rentals - which are still available for Ft Wayne, DuQuoin, & Tulsa.)

(This is all after washing)

Raise car and block

Back-off chassis stops

Brakeclean all fuel fittings, heims, and moving parts

WD all heims and moving parts

Drain oil

Inspect oil filter

Remove fuel parts

Lube fuel pump

Remove air breathers

Remove spark plugs

Check valves and do engine leak down

Cap off fuel fittings

Remove front hubs, etc for cleaning & inspection (Every 2-3 weeks)

Check front spindles/front bushings (remove spindles if necessary)

Remove torsion bars, driveline, jake ladder, etc. to clean and inspect (every 2 weeks)

Remove cap and inspect mag

Clean and check points and blow out mag

Clean and inspect wires

Clean contact points and blow out cap

Grease front spindles (if not removed) and u-joint

“Surgically” clean car with 409,, inspecting frame and components

Nut and bolt check everything

Clean, check and install spark plugs

Install oil filer and fill tank

Clean & check removed torsion bars, shocks, driveline, jake ladder, hubs, bearings, etc.

Regrease driveline, torsion bars, jake ladder, hubs, bearings etc. (Per maintenance sched.)

Install driveline and torsion bars and reconnect (Per maintenance sched.)

Put jake ladder back together and install

Check rear-end for square (after any contact or when help in shop)

Check axle to axle for square (after any contact or when help in shop)

Re-connect shocks and any springs not installed

- Grease front spindles (Per maintenance sched.)

Install front hubs and bearings (Per maintenance sched. – spindles first…if necessary)

Clean fuel parts and lines

Clean and check fuel bypasses for flow

Re-install fuel parts and lines

“Prime” fuel pump

Check and top off fuel

Clean and re-lube breathers

Install air breathers and covers

Put cover on seat and “prep” belts

Bleed brakes (when possible)

Re-block set-up

Check wheels and tires for wear

“Flip” tires

Mark tire stagger sizes

Check water & PS fluid

Put body panels on

Install nerf bars

Mount tires on car and check spacing

Lower and scale (only if time allows)

Check ride heights & "tilt" (for informational purpose only)

Set panard bar

Check toe

Jason Dull

815 494 6002

[email protected]

jasondull.com (For all the Racing News)

|

|

|

|

|

December 08, 2014 at

04:30:45 PM

|

|

|

Joined:

|

07/16/2008

|

|

Posts:

|

979

|

|

|

|

Thanks. That's sort of what we are looking, for but we are looking for something a bit more detailed and laid out in sections and such.

|

|

|

|

|

|

|

December 08, 2014 at

10:05:44 PM

|

|

|

Joined:

|

10/24/2012

|

|

Posts:

|

61

|

|

|

|

Ok, that is pretty much the order I went & what made sense to me. I will watch this thread & see if anybody else replies...I am curious...

Jason Dull

815 494 6002

[email protected]

jasondull.com (For all the Racing News)

|

|

|

|

December 08, 2014 at

10:41:38 PM

|

|

|

Joined:

|

03/23/2007

|

|

Posts:

|

97

|

|

|

|

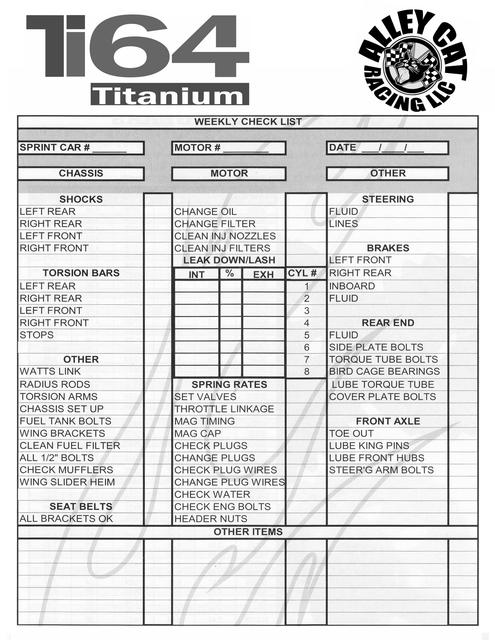

This is what we use....

https://facebook.com/apettas

https://twitter.com/alexpettas

https://www.instagram.com/alexpettas

|

|

|

|

December 09, 2014 at

07:06:35 AM

|

|

|

Joined:

|

12/03/2004

|

|

Posts:

|

298

|

|

|

|

from the XXX website

Winter Maintenenace

This month, we will concentrate on winter maintenance. The season is over (for those in the US), and now is a great time to check and address all those little things that are critical to your race program reliability that may get over looked during the racing season.

� Purge methanol from fuel pump, shutoff's, pill cans, lines, and tank. Keep bladder in a moisture free/temperature controlled area for the winter to prevent cracks. Lube entire fuel system with Marvel’s Mystery Oil or equivalent.

â—? Inspect the master cylinder for any leaks, pressure loss, etc. Rebuild or replace if needed.

â—? Replace brake lines and any fittings that show any wear.

â—? Ensure brake system is pickled/sealed to avoid brake fluid taking on water.

â—? Inspect brake rotors. Replace any that show signs of wear or have a lip.

â—? Replace brake pads.

â—? Test torsion bars. Replace any that do not meet standards.

â—? Replace torsion bar bushings.

â—? Test/Dyno shock bars. Replace any that do not meet standards.

â—? Send steering box (with pump) to a reputable rebuild center to have it inspected, resealed and/or rebuilt.

â—? Inspect wheels for cracks, bends, and any other damage.

â—? Replace all rod ends that have been on the car for the entire season.

â—? Inspect steering quick release. Thoroughly clean and lube if it shows no issues.

â—? Replace seat belts.

â—? Inspect seat for any cracks especially around the bolts.

â—? Rebuild front hubs (new seals, races and bearings if necessary).

â—? Inspect spindles and kingpins for wear. Replace if necessary.

â—? Inspect wings for loss of rivet tension.

â—? Inspect wing posts and wing tees for wear or cracks.

â—? Store any usable tires in a controlled climate.

â—? Disassemble and thoroughly clean birdcage bearings to check for any bind. Replace if necessary.

â—? Inspect rear axle for cracks.

â—? Inspect rear end snout for trueness. Have surfaced if necessary.

â—? Have torque tube trueness checked (on a lathe). Replace if untrue.

â—? Inspect torque ball and housing for surface wear and cracks.

â—? Inspect headers for cracks. Replace gaskets.

|

|

|

|

|

|

|

December 10, 2014 at

12:29:57 AM

|

|

|

Joined:

|

07/16/2008

|

|

Posts:

|

979

|

|

|

|

Pettas ...... thanks, that's exactly what I was looking for.

|

|

|